Welcome to the official website of Hangzhou Shilin Automation Engineering Co., Ltd!

400-8601-107 13906516168

Cancel

clear record

history record

clear record

history record

Product Center

PRODUCT CENTER

ATSL-RN temperature automatic verification system

Product overview

atsl-rn thermocouple thermistor bimetal thermometer full automatic calibration system is a product developed and manufactured by our company with Japanese technology. It is a measurement and control system with PC computer as the core, high-precision imported digital multimeter, imported low potential scanning switch and management software. The operator can conveniently operate the whole process with the mouse under the win7/winxp/unix/linux operating system, and the PC computer system displays the temperature control curve, temperature, verification time and other parameters of the verification furnace (or oil tank, low-temperature tank, etc.) in real time. The system carries out data processing in full accordance with the current national metrological verification regulations, and can print various record forms and verification certificates, and can also retain the original records for future reference. The system completely realizes the automation of the verification process of thermocouples and thermal resistors, that is, automatic temperature control, automatic verification, automatic data processing, automatic printing of verification results, and automatic saving of temperature rise curves. The labor intensity of the operator is greatly reduced, and the work quality of the verification is improved. The device also provides the authentication program and data file management program of the system, which provides convenience for the operator to file, retrieve and query the authentication of the system and the verification results.

main features of the system

1) the whole machine introduces foreign advanced technology;

2) intuitive display and simple operation;

3) complete functions and flexible configuration;

4). High accuracy and high resolution;

5) high degree of automation, high degree of standardization and short verification time;

6) have system certification test skills;

7) the system technology is mature and advanced with high reliability;

8) perfect protective measures.

system composition:

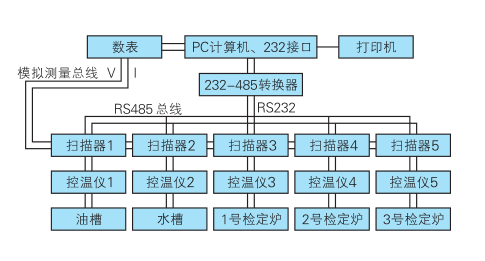

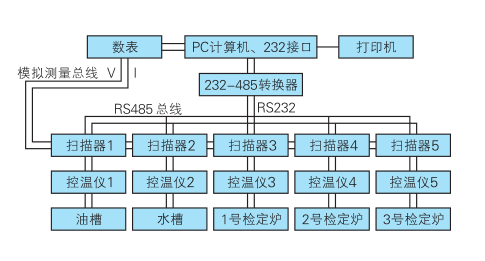

referring to the working mode of DCS system, atsl-rn group control thermotechnical automatic verification system adopts modular structure and distributed control mode. Each channel of temperature control and multi-channel scanning sampling form a separate module unit. Users can configure different numbers of module units according to their needs, but it can't exceed 5 channels at most. PC computer is the upper computer, which is mainly responsible for multi-channel coordination, data sampling and data processing. The temperature control is completed by the lower computer "temperature controller" independently. The digital meter is a multi-channel shared resource, which completes the multi-channel sampling of the verification and measurement data of each module in time sharing.

the overall structure of the system is shown in the figure:

In the figure, the upper computer is PC computer, and the lower computer is digital multimeter, scanner and temperature controller. PC computer interfaces with DMM through RS232 serial bus. PC computer and scanner and temperature controller adopt RS485 serial bus interface. Scanner, temperature controller and thermostat constitute a unit module, which is extended and connected by building block structure. Each unit module can start work independently.

software:

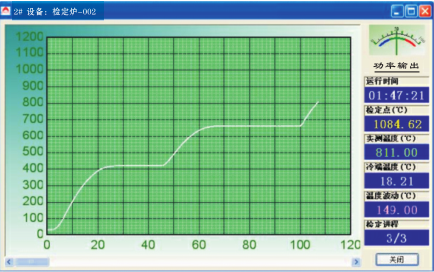

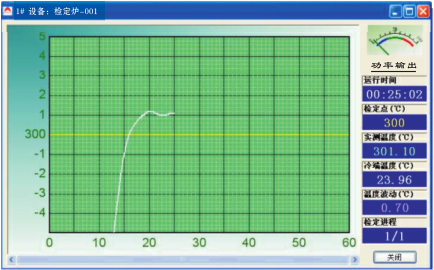

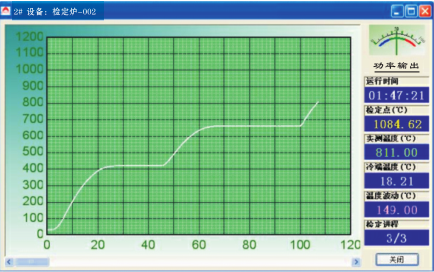

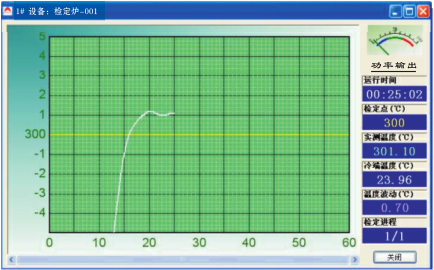

It runs completely under the win7/winxp/unix/linux operating platform with a mouse click. It conforms to the operating habits of Windows environment. The window interface, drop-down menu, and the use of the mouse to select input parameters and process operations are powerful, convenient, flexible and fast. During the verification process, the display shows the temperature change curve of the verification furnace (or oil tank, water tank, etc.), the temperature of the verification furnace (oil tank, water tank), the temperature of the verification point, the verification process, the cold end temperature, the millivolt value of the temperature control couple (the resistance value of the temperature control thermal resistance) and the verification time in real time.

The system is equipped with the certification test module of the thermocouple and thermal resistance verification device itself, which can automatically verify the total uncertainty and repeatability error of the thermocouple and thermal resistance verified by the device, as well as the temperature field of the verification furnace and oil tank, and sort out and print out the certification report. It brings great convenience to the operator for system standard establishment and system review.

equipment service conditions:

ambient temperature: 20 ℃± 5 ℃;

relative humidity: ≤ 75% RH;

use power supply AC220V ± 10%50 ± 1Hz;

the grounding resistance is required to be ≤ 4 Ω;

there should be no high concentration dust and corrosive gas around; It cannot be used and stored in flammable and explosive atmosphere, and there should be certain ventilation conditions.

purpose:

atsl-rn thermocouple thermal resistance bimetal thermometer full automatic verification system can be used to verify various industrial thermocouples, thermal resistances, Expansion thermometers, liquid glass thermometers, bimetal thermometers, pressure thermometers.

meet the standard:

the verification degree of the system is compiled in strict accordance with the relevant national verification regulations and implements ITS-90 international temperature scale, which meets the relevant standards and regulations, including:

● JJG 141-2013 precious metal thermocouples for work;

● JJG 351-1996 cheap metal thermocouples for work;

● JJG 229-2010 industrial platinum and copper thermistors;

● JJG 130-2011 liquid glass thermometer for work;

● JJG 978-2003 high precision mercury glass thermometer for petroleum;

● JJG 310-2002 pressure thermometer;

● JJG 226-2001 bimetal thermometer;

● jjg115-1999 standard copper copper nickel thermocouple

● JJG 75-1995 Standard Platinum Rhodium 10 platinum thermocouple;

● JJG 368-2000 copper copper nickel thermocouple for work;

● jjg1098-2003 calibration specification for thermocouple and thermal resistance automatic measurement system

technical indicators

● parasitic potential of scanning switch: ≤ 0.4 μ V;

● accuracy:

uncertainty of potential measurement ≤ 0.01%;

uncertainty of resistance measurement ≤ 0.01%;

uncertainty of galvanic couple verification ≤ 1.2 ℃;

thermal resistance verification uncertainty ≤ 0.05 ℃;

potential measurement error: ≤± 0.005%;

resistance measurement error: ≤± 0.01%;

● resolution: potential: 0.1 μ V; Resistance: 0.1M Ω;

temperature control accuracy: when verifying the thermocouple, the temperature deviation from the verification point shall not exceed ± 5 ℃;

the temperature deviation from the verification point shall not exceed ± 2 ℃ when verifying the thermal resistance

constant temperature stability: after the constant temperature of thermocouple verification process, the change rate of furnace temperature ≤ 0.2 ℃ /min; After the thermal resistance verification process is constant temperature, the temperature change rate of the oil tank is ≤ 0.04 ℃ /10min;

● verification temperature:

thermocouple (300 ~ 1200) ℃ any 5 ℃ point;

thermal resistance (0 ~ 300) ℃ any 10 ℃ point;

● number of verification: 1 ~ 10 thermocouples can be verified at the same time, and multiple batches of verification at the same temperature point are allowed;

● graduation numbers of verifiable thermocouples: s, K, e, R, B, t, N, J;

● the graduation number of verifiable thermal resistance: PT100, PT50, pt10, cu100, cu50, BA1, Ba2, G;

● power supply: AC power supply 220 ± 22V; 50±1Hz;

● total power: n × 2.0kw (n is the number of modules).

ATSL-RN temperature automatic verification system

Product overview

atsl-rn thermocouple thermistor bimetal thermometer full automatic calibration system is a product developed and manufactured by our company with Japanese technology. It is a measurement and control system with PC computer as the core, high-precision imported digital multimeter, imported low potential scanning switch and management software. The operator can conveniently operate the whole process with the mouse under the win7/winxp/unix/linux operating system, and the PC computer system displays the temperature control curve, temperature, verification time and other parameters of the verification furnace (or oil tank, low-temperature tank, etc.) in real time. The system carries out data processing in full accordance with the current national metrological verification regulations, and can print various record forms and verification certificates, and can also retain the original records for future reference. The system completely realizes the automation of the verification process of thermocouples and thermal resistors, that is, automatic temperature control, automatic verification, automatic data processing, automatic printing of verification results, and automatic saving of temperature rise curves. The labor intensity of the operator is greatly reduced, and the work quality of the verification is improved. The device also provides the authentication program and data file management program of the system, which provides convenience for the operator to file, retrieve and query the authentication of the system and the verification results.

main features of the system

1) the whole machine introduces foreign advanced technology;

2) intuitive display and simple operation;

3) complete functions and flexible configuration;

4). High accuracy and high resolution;

5) high degree of automation, high degree of standardization and short verification time;

6) have system certification test skills;

7) the system technology is mature and advanced with high reliability;

8) perfect protective measures.

system composition:

referring to the working mode of DCS system, atsl-rn group control thermotechnical automatic verification system adopts modular structure and distributed control mode. Each channel of temperature control and multi-channel scanning sampling form a separate module unit. Users can configure different numbers of module units according to their needs, but it can't exceed 5 channels at most. PC computer is the upper computer, which is mainly responsible for multi-channel coordination, data sampling and data processing. The temperature control is completed by the lower computer "temperature controller" independently. The digital meter is a multi-channel shared resource, which completes the multi-channel sampling of the verification and measurement data of each module in time sharing.

the overall structure of the system is shown in the figure:

In the figure, the upper computer is PC computer, and the lower computer is digital multimeter, scanner and temperature controller. PC computer interfaces with DMM through RS232 serial bus. PC computer and scanner and temperature controller adopt RS485 serial bus interface. Scanner, temperature controller and thermostat constitute a unit module, which is extended and connected by building block structure. Each unit module can start work independently.

software:

It runs completely under the win7/winxp/unix/linux operating platform with a mouse click. It conforms to the operating habits of Windows environment. The window interface, drop-down menu, and the use of the mouse to select input parameters and process operations are powerful, convenient, flexible and fast. During the verification process, the display shows the temperature change curve of the verification furnace (or oil tank, water tank, etc.), the temperature of the verification furnace (oil tank, water tank), the temperature of the verification point, the verification process, the cold end temperature, the millivolt value of the temperature control couple (the resistance value of the temperature control thermal resistance) and the verification time in real time.

The system is equipped with the certification test module of the thermocouple and thermal resistance verification device itself, which can automatically verify the total uncertainty and repeatability error of the thermocouple and thermal resistance verified by the device, as well as the temperature field of the verification furnace and oil tank, and sort out and print out the certification report. It brings great convenience to the operator for system standard establishment and system review.

equipment service conditions:

ambient temperature: 20 ℃± 5 ℃;

relative humidity: ≤ 75% RH;

use power supply AC220V ± 10%50 ± 1Hz;

the grounding resistance is required to be ≤ 4 Ω;

there should be no high concentration dust and corrosive gas around; It cannot be used and stored in flammable and explosive atmosphere, and there should be certain ventilation conditions.

purpose:

atsl-rn thermocouple thermal resistance bimetal thermometer full automatic verification system can be used to verify various industrial thermocouples, thermal resistances, Expansion thermometers, liquid glass thermometers, bimetal thermometers, pressure thermometers.

meet the standard:

the verification degree of the system is compiled in strict accordance with the relevant national verification regulations and implements ITS-90 international temperature scale, which meets the relevant standards and regulations, including:

● JJG 141-2013 precious metal thermocouples for work;

● JJG 351-1996 cheap metal thermocouples for work;

● JJG 229-2010 industrial platinum and copper thermistors;

● JJG 130-2011 liquid glass thermometer for work;

● JJG 978-2003 high precision mercury glass thermometer for petroleum;

● JJG 310-2002 pressure thermometer;

● JJG 226-2001 bimetal thermometer;

● jjg115-1999 standard copper copper nickel thermocouple

● JJG 75-1995 Standard Platinum Rhodium 10 platinum thermocouple;

● JJG 368-2000 copper copper nickel thermocouple for work;

● jjg1098-2003 calibration specification for thermocouple and thermal resistance automatic measurement system

technical indicators

● parasitic potential of scanning switch: ≤ 0.4 μ V;

● accuracy:

uncertainty of potential measurement ≤ 0.01%;

uncertainty of resistance measurement ≤ 0.01%;

uncertainty of galvanic couple verification ≤ 1.2 ℃;

thermal resistance verification uncertainty ≤ 0.05 ℃;

potential measurement error: ≤± 0.005%;

resistance measurement error: ≤± 0.01%;

● resolution: potential: 0.1 μ V; Resistance: 0.1M Ω;

temperature control accuracy: when verifying the thermocouple, the temperature deviation from the verification point shall not exceed ± 5 ℃;

the temperature deviation from the verification point shall not exceed ± 2 ℃ when verifying the thermal resistance

constant temperature stability: after the constant temperature of thermocouple verification process, the change rate of furnace temperature ≤ 0.2 ℃ /min; After the thermal resistance verification process is constant temperature, the temperature change rate of the oil tank is ≤ 0.04 ℃ /10min;

● verification temperature:

thermocouple (300 ~ 1200) ℃ any 5 ℃ point;

thermal resistance (0 ~ 300) ℃ any 10 ℃ point;

● number of verification: 1 ~ 10 thermocouples can be verified at the same time, and multiple batches of verification at the same temperature point are allowed;

● graduation numbers of verifiable thermocouples: s, K, e, R, B, t, N, J;

● the graduation number of verifiable thermal resistance: PT100, PT50, pt10, cu100, cu50, BA1, Ba2, G;

● power supply: AC power supply 220 ± 22V; 50±1Hz;

● total power: n × 2.0kw (n is the number of modules).

Related Products

平台信息提交-隐私协议

● 隐私权政策

我们致力于保护您在使用本网站时所提供的隐私、私人资料以及个人的资料(统称“个人资料”)。使我们在收集、使用、储存和传送个人资料方面符合(与个人资料隐私有关的法律法规)及消费者保护方面的最高标准。为确保您对本网站在处理个人资料上有充分信心,您切要详细阅读及理解隐私政策的条文。 本网站(下称“我们”)尊重并保护用户隐私, 特别时您一旦使用本网站,将被视为接受、同意、承诺和确认本隐私协议;您在自愿下连同所需的同意向我们披露个人资料;您会遵守本隐私政策的任何修改;您同意我们的相关业务人员就您可能会感兴趣的产品和服务与您联络(除非您已经表示不想收到该等讯息)。被收集的个人资料的种类经您的同意、我们会收集、管理和监控个人资料。

1、 适用范围

为用户提供更好、更优、更个性化的服务是本网站坚持不懈的追求,也希望通过我们提供的服务可以更方便您的需求。本隐私权政策适用于本网站提供的所有关于信息收集的服务,您访问本网站及使用本网站提供的服务均使用本隐私权政策。

2、 我们收集哪些信息

为了向您提供我们的各项服务,您需要提供个人资料信息,其中包括个人资料和不具名的资料,包括但不限于:个人资料(您的姓名、性别、年龄、出生日期、电话号码、传真号码、住址或通讯地址、电子邮箱地址等)。

3、 我们如何使用收集到的信息

收集个人资料和不具名的资料目的及用途如下:通过本网站向您提供我们的各项服务;当您使用我们的网站时,能辨认以及确认您的身份;让您使用本网站时得到为您而设的服务;本网站的相关业务人员有需要时可以与您联系;让您在使用本网站时更加方便;您提供给我们的个人资料及不具名资料,只保留到搜集的目的已达到的时候,除非因适用的法律法规之规定而继续保留。个人资料的拥有权及披露在我们网站上所收集的一切资料都由我们所拥有,不会出租或出售给任何无关的第三方。

4、 我们如何保护信息

对于个人资料的保护,我们实施妥适的实物、电子、管理的措施来保护和保障您的个人资料的安全。我们尽力确保通过本网站所收集的任何个人资料皆免于任何与我们无关的第三者的滋扰。我们采取的安全措施不限于: 实物措施:存有您个人资料的记录会被存放在有锁的地方 电子措施:存有您个人资料的电脑数据会被存放在受严格登录限制的电脑系统和存储媒体上 管理措施:只有经过我们授权的职员才能接触到您的个人资料,这些职员需要遵守我们个人资料保密的内部规则 若您知悉本网站上有任何安全方面的漏洞,请不要迟疑去联络我们,使我们可以尽快采取妥适的行动;尽管实施了上述安全措施,我们不能保证资料在互联网上的输送绝对安全,因此我们不能绝对保证您通过本网站提供给我们的个人资料及不具名的资料在一切时候都是安全的。对任何因未经授权而接触您个人资料所发生的事件我们一概不承担责任,于这方面产生或导致的任何损失和损害,我们也不负责赔偿。

5、 未成年人保护法

未成年人在无任何家长或监护人相信有未成年人在未经家长或监护人批准或同意下向本网站提供了个人自来哦,请及时联系本网站所公示电话及客服电话等,以确保资料被除去。

6、 隐私政策的修定与生效

随着本网站的服务范围扩大,我们可能适时修订《法律声明及隐私权政策》,该等修订构成本《法律声明及隐私权政策》的一部分。为避免您不能及时获知改等修订,请您经常阅读本《法律声明及隐私权政策》。无论何种方式,如您继续使用我们的服务,即表示统一受经修订本《法律声明及隐私权政策》的约束。

浏览器自带分享功能也很好用哦~

浏览器自带分享功能也很好用哦~