Welcome to the official website of Hangzhou Shilin Automation Engineering Co., Ltd!

400-8601-107 13906516168

Cancel

clear record

history record

clear record

history record

Product Center

PRODUCT CENTER

APSL801 pneumatic fully automatic piston pressure gauge

1. Product overview

apsl801 pneumatic full-automatic piston pressure gauge is a product designed and developed by our company with advanced anti-wear patent. It is fully automatic to load weights and pressurize. In the verification process, wear prevention can be achieved at any time to ensure that the maximum error of the piston system in a verification cycle does not exceed the allowable error. The system includes the function of full-automatic pressure calibration table, which has the functions of sending 24V power supply, measuring real-time pressure, input current, input voltage, piston position, weight rotation speed, piston head temperature, humidity and so on. It can fully calibrate pressure transmitters, digital pressure gauges, precision pressure gauges and so on, and automatically set the verification points. The verification speed is fast, and it takes only about 10 minutes to verify the two pressure transmitters.

before starting the verification, automatically start the high-power vacuum pump, quickly pump the pressure in the vacuum cover to within 20Pa, then automatically load the weight according to the fixed value, and automatically pressurize until the piston is jacked up and stabilized for a specified time, and then enter the lower point.

Since the atmospheric pressure sensor is installed, the absolute pressure and gauge pressure can be switched.

as shown in the figure below, the fixed value can be operated by the "set value increase" and "set value decrease" keys according to the control step step method, or it can be directly operated by the input window on the touch screen, and the control step can be modified at will; After the piston is jacked, the descent speed is automatically calculated. When the pressure is controlled, the weight will automatically rotate, and when it stops, the rotation will automatically stop; Automatically measure two circuits of current, and can verify two absolute pressure transmitters at the same time.

2. Function

Automatically verify the pressure transmitter, automatically record the verification results, and automatically print the verification report;

Automatic verification of precision digital pressure gauge, automatic recording of verification results, automatic printing of verification report;

Automatic verification of precision pressure gauge, automatic calculation of error, automatic recording of verification results, automatic printing of verification report.

If the kilogram weight is used, the piston pressure gauge can be calibrated automatically.

3. Related patents

two hundred and one billion eight hundred and ten million five hundred and sixty-seven thousand four hundred and eight point five

two hundred and one billion eight hundred and twenty million eight hundred and fifty-eight thousand nine hundred and twenty-nine point one

two hundred and one billion nine hundred and twenty million four hundred and sixty-two thousand two hundred and seventy-five point five

two hundred and one billion nine hundred and ten million two hundred and seventy-six thousand two hundred and ninety-seven point seven

4. Technical indicators

1) Absolute pressure and positive pressure measurement range and resolution:

测量范围 | 分辨率 | 测量范围 | 分辨率 | |

(10-160)kPaa | 5kPa | (50-2500)kPaa | 50kPa | |

(10-250)kPaa | 5kPa | (0.1-4)MPaa | 100kPa | |

(10-400)kPaa | 5kPa | (0.1-6)MPaa | 100kPa | |

(30-600)kPaa | 10kPa | (0.2-7)MPaa | 200kPa | |

(30-700)kPaa | 15kPa | (0.2-10)MPaa | 200kPa | |

(30-1000)kPaa | 30kPa | (0.2-16)MPaa | 300kPa | |

(30-1600)kPaa | 30kPa |

2) Measurement range and resolution of positive and negative voltage

测量范围 | 分辨率 |

(-100~-10~10~160)kPa | 5kPa |

(-100~-10~10~250)kPa | 5kPa |

(-100~-10~10~400)kPa | 10kPa |

(-100~-10~10~600)kPa | 10kPa |

(-100~-20~20~700)kPa | 20kPa |

(-100~-20~20~1000)kPa | 20kPa |

(-100~-20~20~1600)kPa | 40kPa |

(-100~-50~50~2500)kPa | 50kPa |

3) Accuracy:

Pressure: 0.005, 0.01, 0.02, 0.05.

Current: (0 ~ 22) MA, level 0.02.

Voltage: (0 ~ 5.5) V, level 0.02.

4) Others:

24V power output function, with 2 electric quantity measurement channels, which is convenient to verify the pressure transmitter.

Weight material: non magnetic stainless steel.

Material of piston rod and cylinder: tungsten carbide.

Pneumatic working medium: high purity nitrogen.

Overall dimension: Ф 400*500mm

It can be connected with tmms-2000 software to automatically print the verification report.

You can query the verification results on the touch screen or export the verification results with a USB flash disk.

5. Performance characteristics

Fully automatic loading of weights.

All weights rotate synchronously, and there is no wear during weight loading.

Built in special pressure source, automatic pressurization.

Built in pressure, current, voltage, temperature and humidity sensors.

Built in piston position and speed measurement.

Conform to the national metrological verification regulations of jjg1086-2013 gas piston pressure gauge and jjg99-2006 weights.

Full automatic weight addition and subtraction: the weight not placed on the hanging blue rotates synchronously with the weight placed on the hanging blue. The weight is loaded at the synchronous speed. The weight loading process has no wear, good stability and fast pressurization speed.

Wear free anti break rod piston system is adopted, rolling mode is adopted at the limit position, and the piston disc is free of wear.

The full-automatic pressure source dedicated to the piston is used for full-automatic pressurization, which has fast pressurization speed and fast stability speed.

Digital terminal monitoring parameters: touch screen operation, which displays information such as ambient atmospheric pressure, ambient temperature, ambient humidity, current pressure, piston position, piston temperature, piston speed and weight combination;

Correction of pressure value: parameters such as pressure, gravity acceleration and piston temperature in the vacuum cover are automatically corrected by software;

Automatic weighting: block weights and cylindrical weights are freely combined and automatically loaded; Internal hanging weight is adopted, with no failure point and extremely low failure rate;

Three tested fast interfaces are configured as standard, and multiple (3-4) extensions can be configured to verify multiple sensors;

Function: automatic verification of pressure transmitter, digital pressure gauge and pressure gauge.

6. Advantages

6.1 wear resistance is achieved

with patented anti-wear design (patent numbers: 201920462275.5 and 201910276297.7), the weight quality stability can be maintained for a long time.

with patented anti-wear design (patent numbers: 201810567408.5 and 201820858929.1), the quality stability of piston chassis can be maintained for a long time.

1) all weights (the suspended weight and the weight loaded on the hanging blue) rotate synchronously, and there is no relative movement and wear during the weight loading process.

2) the limit of piston disc adopts bearing limit. The piston rotates at its limit position, and the piston head is free of wear under any working condition.

at present, the full-automatic piston pressure gauge, including imported ones, has a relatively slow pressure stabilization speed. The main reason is that the weight can be rotated only when the piston is in suspension. When the piston is at the upper and lower limits, it is not allowed to rotate the weight because of fear of wear. Moreover, the piston pressure gauge is a precision instrument, and impact is not allowed, so the acceleration of rotating and stopping the weight must be very slow. Resulting in a slow stabilization speed. It usually takes 3-5 minutes.

apsl801 fundamentally solves the problem, and the weight can keep rotating all the time. It only takes 30 to 60 seconds to stabilize a pressure.

only by preventing wear and tear, the annual stability can be guaranteed, the verification speed can be fast, and the efficiency can be improved.

6.2 internal hanging weights are used, with few faults

the circumferential hook of apsl801 weight is processed as a whole with the weight. There is no moving part. When loading the weight, the four sides rise and fall at the same time, which is quite stable. There is basically no fault point, and generally there will be no fault. Sudden power failure during use will not cause failure.

there are many failure points of pneumatic loading. Each weight has three telescopic hooks or rotating hooks, which are driven by the cylinder. Due to wear and lubrication problems, it is easy to fail, and any one of them will not work if it fails. If a hook fails, the weight will be unbalanced and fail. Pneumatic loading has high requirements for air source. Sudden power failure or gas failure during use may cause failure.

6.3 stable weight loading

apsl801 loading weight is realized by lifting and dropping the suspended weight, which is relatively stable without impact. Pressurization and loading weight are carried out at the same time.

when loading binary weights, all weights must be put down, and then the unused weights must be hoisted. Moreover, the speed is fast (the cylinder controls the hook, and it is impossible to move slowly) and the impact is large. During the downward stroke, the piston rod drops rapidly, and then rises rapidly. Generally, an automatic shut-off valve is equipped in the front of the tested connecting pipe to ensure that the pressure overshoot or too low does not affect the tested instrument during the weight switching process.

6.4 piston pressure gauge and pressure source are arranged separately, without vibration

apsl801 piston pressure gauge and pressure source are arranged separately and connected through wires and pipes. The small vibration of the motor of the pressure source during operation will not be transmitted to the piston pressure gauge, ensuring that the piston pressure gauge has accurate measurement, fast pressure stabilization speed and long service life.

6.5 others

built in pressure, current, voltage, temperature and humidity sensors, sent by 24V power supply. It is convenient to calibrate the pressure transmitter.

built in piston position, speed and lifting speed measurement.

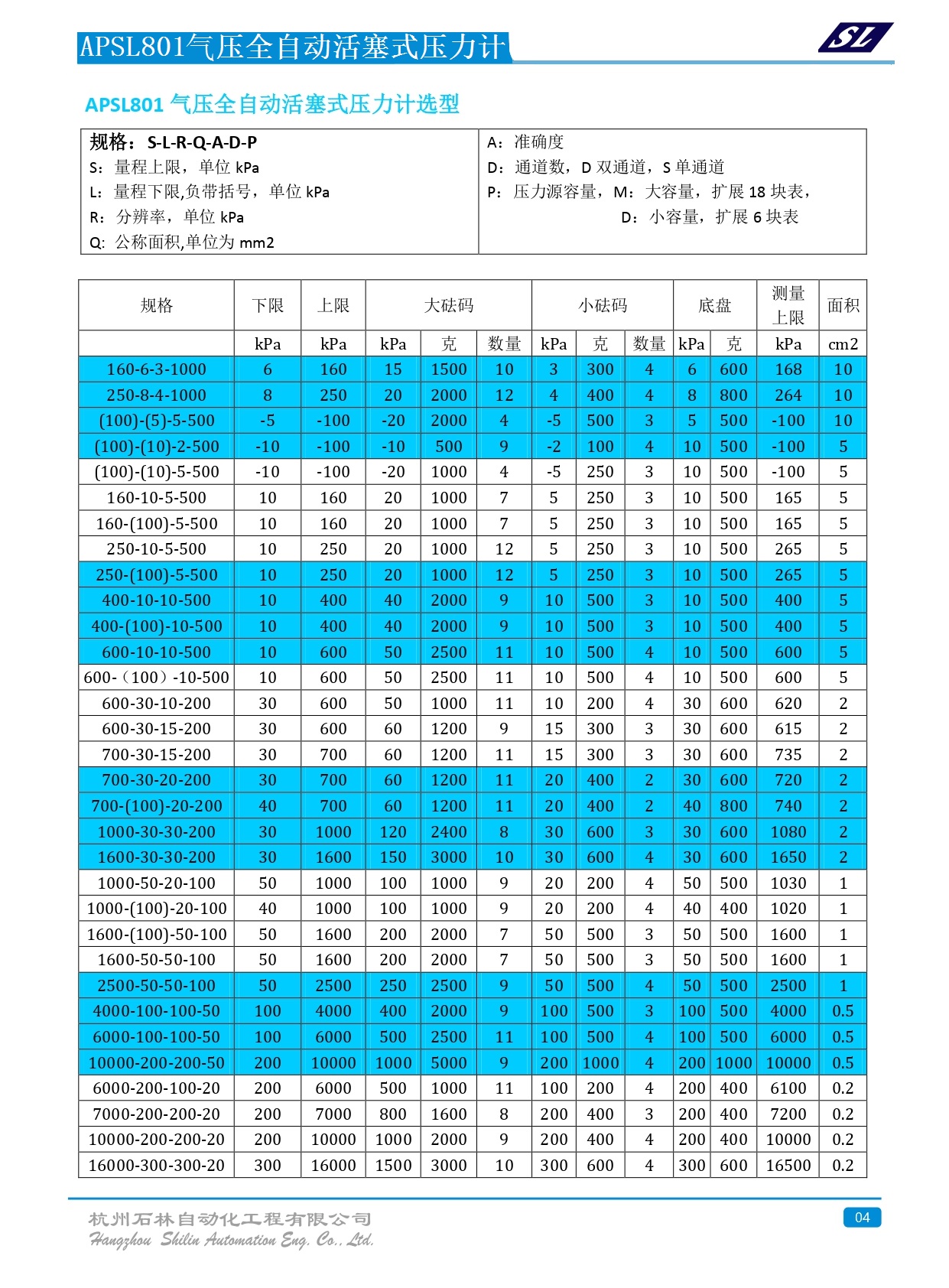

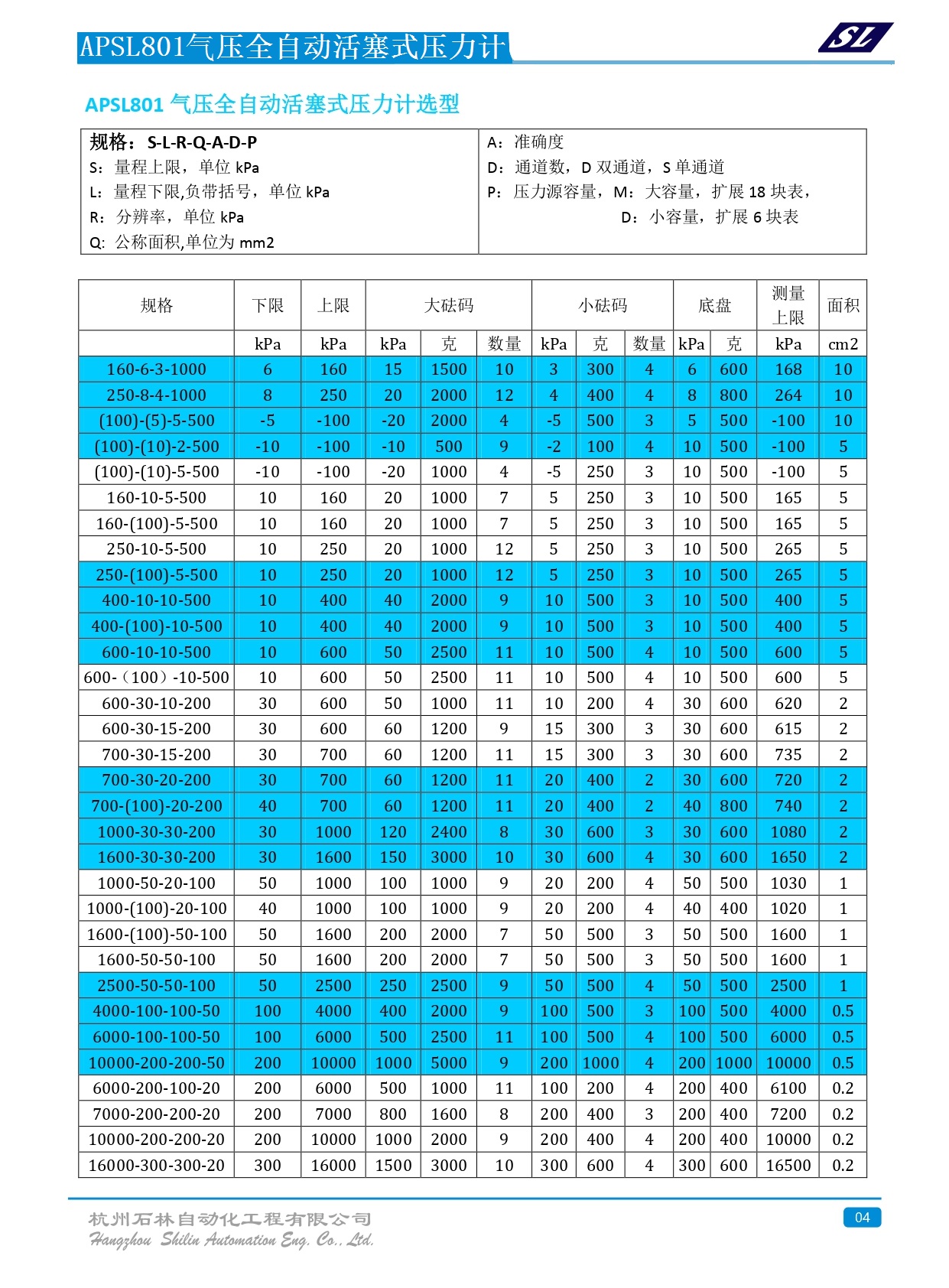

7. Model selection

APSL801 pneumatic fully automatic piston pressure gauge

1. Product overview

apsl801 pneumatic full-automatic piston pressure gauge is a product designed and developed by our company with advanced anti-wear patent. It is fully automatic to load weights and pressurize. In the verification process, wear prevention can be achieved at any time to ensure that the maximum error of the piston system in a verification cycle does not exceed the allowable error. The system includes the function of full-automatic pressure calibration table, which has the functions of sending 24V power supply, measuring real-time pressure, input current, input voltage, piston position, weight rotation speed, piston head temperature, humidity and so on. It can fully calibrate pressure transmitters, digital pressure gauges, precision pressure gauges and so on, and automatically set the verification points. The verification speed is fast, and it takes only about 10 minutes to verify the two pressure transmitters.

before starting the verification, automatically start the high-power vacuum pump, quickly pump the pressure in the vacuum cover to within 20Pa, then automatically load the weight according to the fixed value, and automatically pressurize until the piston is jacked up and stabilized for a specified time, and then enter the lower point.

Since the atmospheric pressure sensor is installed, the absolute pressure and gauge pressure can be switched.

as shown in the figure below, the fixed value can be operated by the "set value increase" and "set value decrease" keys according to the control step step method, or it can be directly operated by the input window on the touch screen, and the control step can be modified at will; After the piston is jacked, the descent speed is automatically calculated. When the pressure is controlled, the weight will automatically rotate, and when it stops, the rotation will automatically stop; Automatically measure two circuits of current, and can verify two absolute pressure transmitters at the same time.

2. Function

Automatically verify the pressure transmitter, automatically record the verification results, and automatically print the verification report;

Automatic verification of precision digital pressure gauge, automatic recording of verification results, automatic printing of verification report;

Automatic verification of precision pressure gauge, automatic calculation of error, automatic recording of verification results, automatic printing of verification report.

If the kilogram weight is used, the piston pressure gauge can be calibrated automatically.

3. Related patents

two hundred and one billion eight hundred and ten million five hundred and sixty-seven thousand four hundred and eight point five

two hundred and one billion eight hundred and twenty million eight hundred and fifty-eight thousand nine hundred and twenty-nine point one

two hundred and one billion nine hundred and twenty million four hundred and sixty-two thousand two hundred and seventy-five point five

two hundred and one billion nine hundred and ten million two hundred and seventy-six thousand two hundred and ninety-seven point seven

4. Technical indicators

1) Absolute pressure and positive pressure measurement range and resolution:

测量范围 | 分辨率 | 测量范围 | 分辨率 | |

(10-160)kPaa | 5kPa | (50-2500)kPaa | 50kPa | |

(10-250)kPaa | 5kPa | (0.1-4)MPaa | 100kPa | |

(10-400)kPaa | 5kPa | (0.1-6)MPaa | 100kPa | |

(30-600)kPaa | 10kPa | (0.2-7)MPaa | 200kPa | |

(30-700)kPaa | 15kPa | (0.2-10)MPaa | 200kPa | |

(30-1000)kPaa | 30kPa | (0.2-16)MPaa | 300kPa | |

(30-1600)kPaa | 30kPa |

2) Measurement range and resolution of positive and negative voltage

测量范围 | 分辨率 |

(-100~-10~10~160)kPa | 5kPa |

(-100~-10~10~250)kPa | 5kPa |

(-100~-10~10~400)kPa | 10kPa |

(-100~-10~10~600)kPa | 10kPa |

(-100~-20~20~700)kPa | 20kPa |

(-100~-20~20~1000)kPa | 20kPa |

(-100~-20~20~1600)kPa | 40kPa |

(-100~-50~50~2500)kPa | 50kPa |

3) Accuracy:

Pressure: 0.005, 0.01, 0.02, 0.05.

Current: (0 ~ 22) MA, level 0.02.

Voltage: (0 ~ 5.5) V, level 0.02.

4) Others:

24V power output function, with 2 electric quantity measurement channels, which is convenient to verify the pressure transmitter.

Weight material: non magnetic stainless steel.

Material of piston rod and cylinder: tungsten carbide.

Pneumatic working medium: high purity nitrogen.

Overall dimension: Ф 400*500mm

It can be connected with tmms-2000 software to automatically print the verification report.

You can query the verification results on the touch screen or export the verification results with a USB flash disk.

5. Performance characteristics

Fully automatic loading of weights.

All weights rotate synchronously, and there is no wear during weight loading.

Built in special pressure source, automatic pressurization.

Built in pressure, current, voltage, temperature and humidity sensors.

Built in piston position and speed measurement.

Conform to the national metrological verification regulations of jjg1086-2013 gas piston pressure gauge and jjg99-2006 weights.

Full automatic weight addition and subtraction: the weight not placed on the hanging blue rotates synchronously with the weight placed on the hanging blue. The weight is loaded at the synchronous speed. The weight loading process has no wear, good stability and fast pressurization speed.

Wear free anti break rod piston system is adopted, rolling mode is adopted at the limit position, and the piston disc is free of wear.

The full-automatic pressure source dedicated to the piston is used for full-automatic pressurization, which has fast pressurization speed and fast stability speed.

Digital terminal monitoring parameters: touch screen operation, which displays information such as ambient atmospheric pressure, ambient temperature, ambient humidity, current pressure, piston position, piston temperature, piston speed and weight combination;

Correction of pressure value: parameters such as pressure, gravity acceleration and piston temperature in the vacuum cover are automatically corrected by software;

Automatic weighting: block weights and cylindrical weights are freely combined and automatically loaded; Internal hanging weight is adopted, with no failure point and extremely low failure rate;

Three tested fast interfaces are configured as standard, and multiple (3-4) extensions can be configured to verify multiple sensors;

Function: automatic verification of pressure transmitter, digital pressure gauge and pressure gauge.

6. Advantages

6.1 wear resistance is achieved

with patented anti-wear design (patent numbers: 201920462275.5 and 201910276297.7), the weight quality stability can be maintained for a long time.

with patented anti-wear design (patent numbers: 201810567408.5 and 201820858929.1), the quality stability of piston chassis can be maintained for a long time.

1) all weights (the suspended weight and the weight loaded on the hanging blue) rotate synchronously, and there is no relative movement and wear during the weight loading process.

2) the limit of piston disc adopts bearing limit. The piston rotates at its limit position, and the piston head is free of wear under any working condition.

at present, the full-automatic piston pressure gauge, including imported ones, has a relatively slow pressure stabilization speed. The main reason is that the weight can be rotated only when the piston is in suspension. When the piston is at the upper and lower limits, it is not allowed to rotate the weight because of fear of wear. Moreover, the piston pressure gauge is a precision instrument, and impact is not allowed, so the acceleration of rotating and stopping the weight must be very slow. Resulting in a slow stabilization speed. It usually takes 3-5 minutes.

apsl801 fundamentally solves the problem, and the weight can keep rotating all the time. It only takes 30 to 60 seconds to stabilize a pressure.

only by preventing wear and tear, the annual stability can be guaranteed, the verification speed can be fast, and the efficiency can be improved.

6.2 internal hanging weights are used, with few faults

the circumferential hook of apsl801 weight is processed as a whole with the weight. There is no moving part. When loading the weight, the four sides rise and fall at the same time, which is quite stable. There is basically no fault point, and generally there will be no fault. Sudden power failure during use will not cause failure.

there are many failure points of pneumatic loading. Each weight has three telescopic hooks or rotating hooks, which are driven by the cylinder. Due to wear and lubrication problems, it is easy to fail, and any one of them will not work if it fails. If a hook fails, the weight will be unbalanced and fail. Pneumatic loading has high requirements for air source. Sudden power failure or gas failure during use may cause failure.

6.3 stable weight loading

apsl801 loading weight is realized by lifting and dropping the suspended weight, which is relatively stable without impact. Pressurization and loading weight are carried out at the same time.

when loading binary weights, all weights must be put down, and then the unused weights must be hoisted. Moreover, the speed is fast (the cylinder controls the hook, and it is impossible to move slowly) and the impact is large. During the downward stroke, the piston rod drops rapidly, and then rises rapidly. Generally, an automatic shut-off valve is equipped in the front of the tested connecting pipe to ensure that the pressure overshoot or too low does not affect the tested instrument during the weight switching process.

6.4 piston pressure gauge and pressure source are arranged separately, without vibration

apsl801 piston pressure gauge and pressure source are arranged separately and connected through wires and pipes. The small vibration of the motor of the pressure source during operation will not be transmitted to the piston pressure gauge, ensuring that the piston pressure gauge has accurate measurement, fast pressure stabilization speed and long service life.

6.5 others

built in pressure, current, voltage, temperature and humidity sensors, sent by 24V power supply. It is convenient to calibrate the pressure transmitter.

built in piston position, speed and lifting speed measurement.

7. Model selection

Related Products

平台信息提交-隐私协议

● 隐私权政策

我们致力于保护您在使用本网站时所提供的隐私、私人资料以及个人的资料(统称“个人资料”)。使我们在收集、使用、储存和传送个人资料方面符合(与个人资料隐私有关的法律法规)及消费者保护方面的最高标准。为确保您对本网站在处理个人资料上有充分信心,您切要详细阅读及理解隐私政策的条文。 本网站(下称“我们”)尊重并保护用户隐私, 特别时您一旦使用本网站,将被视为接受、同意、承诺和确认本隐私协议;您在自愿下连同所需的同意向我们披露个人资料;您会遵守本隐私政策的任何修改;您同意我们的相关业务人员就您可能会感兴趣的产品和服务与您联络(除非您已经表示不想收到该等讯息)。被收集的个人资料的种类经您的同意、我们会收集、管理和监控个人资料。

1、 适用范围

为用户提供更好、更优、更个性化的服务是本网站坚持不懈的追求,也希望通过我们提供的服务可以更方便您的需求。本隐私权政策适用于本网站提供的所有关于信息收集的服务,您访问本网站及使用本网站提供的服务均使用本隐私权政策。

2、 我们收集哪些信息

为了向您提供我们的各项服务,您需要提供个人资料信息,其中包括个人资料和不具名的资料,包括但不限于:个人资料(您的姓名、性别、年龄、出生日期、电话号码、传真号码、住址或通讯地址、电子邮箱地址等)。

3、 我们如何使用收集到的信息

收集个人资料和不具名的资料目的及用途如下:通过本网站向您提供我们的各项服务;当您使用我们的网站时,能辨认以及确认您的身份;让您使用本网站时得到为您而设的服务;本网站的相关业务人员有需要时可以与您联系;让您在使用本网站时更加方便;您提供给我们的个人资料及不具名资料,只保留到搜集的目的已达到的时候,除非因适用的法律法规之规定而继续保留。个人资料的拥有权及披露在我们网站上所收集的一切资料都由我们所拥有,不会出租或出售给任何无关的第三方。

4、 我们如何保护信息

对于个人资料的保护,我们实施妥适的实物、电子、管理的措施来保护和保障您的个人资料的安全。我们尽力确保通过本网站所收集的任何个人资料皆免于任何与我们无关的第三者的滋扰。我们采取的安全措施不限于: 实物措施:存有您个人资料的记录会被存放在有锁的地方 电子措施:存有您个人资料的电脑数据会被存放在受严格登录限制的电脑系统和存储媒体上 管理措施:只有经过我们授权的职员才能接触到您的个人资料,这些职员需要遵守我们个人资料保密的内部规则 若您知悉本网站上有任何安全方面的漏洞,请不要迟疑去联络我们,使我们可以尽快采取妥适的行动;尽管实施了上述安全措施,我们不能保证资料在互联网上的输送绝对安全,因此我们不能绝对保证您通过本网站提供给我们的个人资料及不具名的资料在一切时候都是安全的。对任何因未经授权而接触您个人资料所发生的事件我们一概不承担责任,于这方面产生或导致的任何损失和损害,我们也不负责赔偿。

5、 未成年人保护法

未成年人在无任何家长或监护人相信有未成年人在未经家长或监护人批准或同意下向本网站提供了个人自来哦,请及时联系本网站所公示电话及客服电话等,以确保资料被除去。

6、 隐私政策的修定与生效

随着本网站的服务范围扩大,我们可能适时修订《法律声明及隐私权政策》,该等修订构成本《法律声明及隐私权政策》的一部分。为避免您不能及时获知改等修订,请您经常阅读本《法律声明及隐私权政策》。无论何种方式,如您继续使用我们的服务,即表示统一受经修订本《法律声明及隐私权政策》的约束。

浏览器自带分享功能也很好用哦~

浏览器自带分享功能也很好用哦~