Welcome to the official website of Hangzhou Shilin Automation Engineering Co., Ltd!

400-8601-107 13906516168

Cancel

clear record

history record

clear record

history record

Product Center

PRODUCT CENTER

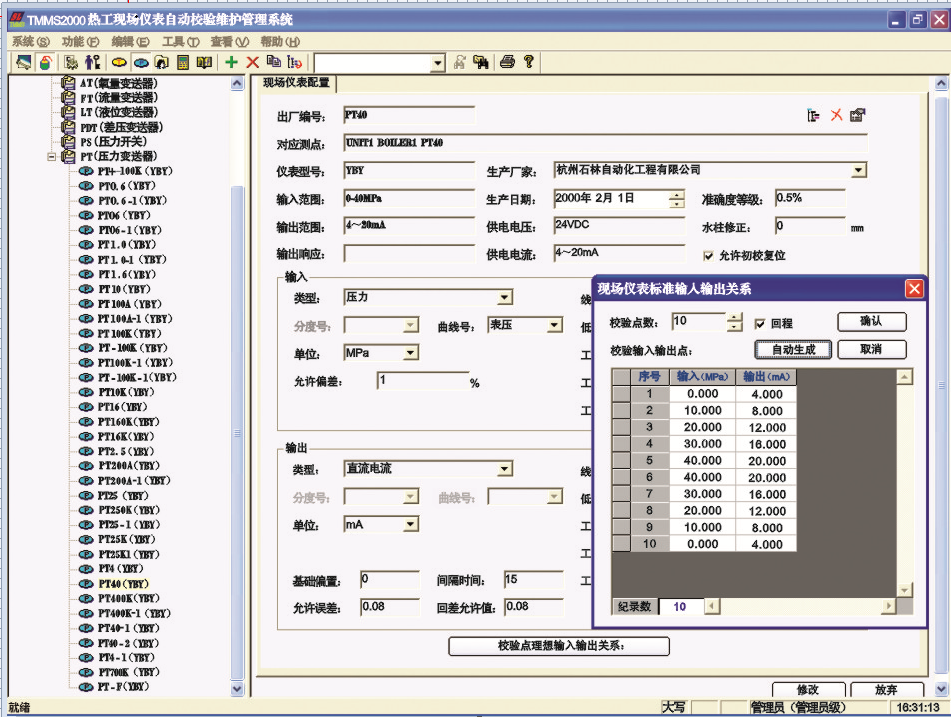

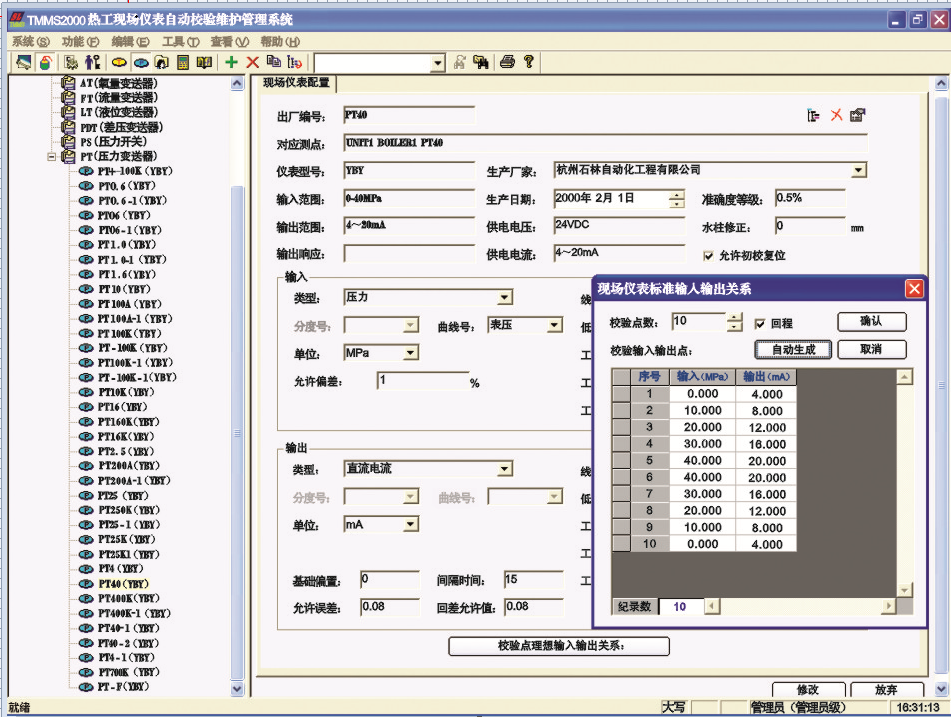

TMMS-2000 instrument automatic verification maintenance management system

Product overview

this software is also called full-automatic pressure verification system software. It can not only form a full-automatic pressure verification system with apsl501 series full-automatic pressure verification platform, apsl503 intelligent pressure controller, apsl 311 series precision pressure calibrator, but also manage pressure, temperature, flow, liquid level, current, voltage and other instruments, forming an instrument automatic verification maintenance management system.

the full-automatic pressure verification system is divided into field full-automatic pressure verification system and verification room full-automatic pressure verification system.

on site automatic pressure verification system: it is composed of automatic verification software, apsl501 series or 601 series automatic pressure verification platform, and apsl311 series precision pressure calibrators (collectively referred to as "pressure calibrators"), which are suitable for on-site application. The automatic verification software downloads the field instrument parameters to be verified to the pressure calibrator. During the verification process, the calibrator automatically records the data in the memory. After the verification, upload the verification results back to the automatic verification software for data processing and report printing.

automatic verification system of verification room: it is composed of automatic verification software, apsl501 or 601 series automatic pressure verification platform, apsl311 series precision pressure calibrator, apsl503 series intelligent pressure controller, apsl801 automatic piston pressure gauge, and apsl803 series automatic pressure verification device (collectively referred to as "automatic pressure verification device"), which is suitable for use in the verification room. The "full automatic pressure verification device" is directly connected to the computer for real-time verification, forming a full-automatic pressure verification system. After the instrument is verified, the data processing work is also completed synchronously, and the verification report and verification certificate can be printed immediately.

software function

automatic verification of thermal instruments:

fully automatic verification of pressure transmitter, pressure switch and pressure gauge: as long as you click the mouse (or start button), you can control apsl type or ease type full-automatic pressure verification platform according to database settings, and automatically complete pressurization, decompression, pressure stabilization, data recording, error analysis, printing reports and certificates.

support multiple verification platforms and multiple verification methods:

one computer can be connected with three apsl or easy full-automatic pressure calibration tables at the same time for real-time calibration. Support single test point verification, double test point verification, four test point verification, upload and download verification methods.

comprehensively manage the parameters of field instruments:

(1) management process measurement point parameters

(2) manage field instrument parameters

automatic management of verification results:

it can manage the calibration results for many years: two test results before and after adjustment.

overall management personnel and standard equipment:

(1) manage the verification personnel

(2) management personnel

(3) management standard equipment

it is convenient to generate work task list

(1) the system can print out the list of instruments that must be calibrated, the list of instruments that fail to be calibrated and the list of instruments that fail to be checked (have been scheduled for calibration, but have not been calibrated for some reason) within a certain period of time (such as a month, a week) in a very short time, which is very helpful for managers to arrange work.

(2) the pass rate before calibration can be counted.

automatically print the verification report:

the format of the verification report can be specified by the user. There can be many formats.

features of software:

integration of management and verification. The management system can directly communicate with the automatic pressure test bench or calibrator, and the verification data can be directly entered into the management database.

the verification of pressure transmitter, pressure switch and pressure indicator is integrated. The verification results are automatically identified and stored in the corresponding database.

the verification results can be entered through communication or manually. The system automatically completes error analysis and automatically generates the verification result database, verification report and verification certificate.

the system can ensure the authenticity of the verification report. The verification results are changed without legal person, which avoids the usual phenomenon of filling in the verification report by memory afterwards, so as to ensure the authenticity, credibility, science and standardization of the verification report.

this system can greatly improve the efficiency of verification.

connectable verification equipment

tmms-2000 instrument automatic verification maintenance management system can be connected with the following verification equipment:

apsl 501 series or 601 series automatic pressure calibration table or easy type automatic pressure calibration table

apsl 311 series precision pressure calibrator or 312 series precision pressure gauge

beta950 or beta960 multifunctional calibrator

beta325 pressure calibrator

beta135, 235 multi-function calibrator

Drucker calibrator

tc2000 low temperature verification furnace

classification of software:

this software is divided into network version, single machine full version, single machine 560 point software and single machine 56 point software.

(1) the network version software package supports network functions and can be used on the MIS network in the factory. It must be equipped with a server, and has the functions of on-site full-automatic pressure verification system and verification room full-automatic pressure verification system. The database capacity is 65000 points.

(2) stand alone full version software package can only be used on one computer. At the same time, it has the functions of field full-automatic pressure verification system and verification room full-automatic pressure verification system. The database capacity is 5000 points.

(3) single machine 560 point software package can only be used on one computer. At the same time, it has the functions of on-site full-automatic pressure verification system and verification room full-automatic pressure verification system, and can be connected with apsl, easy, ease calibration platforms and beta325 pressure calibrators. The database capacity is 560 points.

TMMS-2000 instrument automatic verification maintenance management system

Product overview

this software is also called full-automatic pressure verification system software. It can not only form a full-automatic pressure verification system with apsl501 series full-automatic pressure verification platform, apsl503 intelligent pressure controller, apsl 311 series precision pressure calibrator, but also manage pressure, temperature, flow, liquid level, current, voltage and other instruments, forming an instrument automatic verification maintenance management system.

the full-automatic pressure verification system is divided into field full-automatic pressure verification system and verification room full-automatic pressure verification system.

on site automatic pressure verification system: it is composed of automatic verification software, apsl501 series or 601 series automatic pressure verification platform, and apsl311 series precision pressure calibrators (collectively referred to as "pressure calibrators"), which are suitable for on-site application. The automatic verification software downloads the field instrument parameters to be verified to the pressure calibrator. During the verification process, the calibrator automatically records the data in the memory. After the verification, upload the verification results back to the automatic verification software for data processing and report printing.

automatic verification system of verification room: it is composed of automatic verification software, apsl501 or 601 series automatic pressure verification platform, apsl311 series precision pressure calibrator, apsl503 series intelligent pressure controller, apsl801 automatic piston pressure gauge, and apsl803 series automatic pressure verification device (collectively referred to as "automatic pressure verification device"), which is suitable for use in the verification room. The "full automatic pressure verification device" is directly connected to the computer for real-time verification, forming a full-automatic pressure verification system. After the instrument is verified, the data processing work is also completed synchronously, and the verification report and verification certificate can be printed immediately.

software function

automatic verification of thermal instruments:

fully automatic verification of pressure transmitter, pressure switch and pressure gauge: as long as you click the mouse (or start button), you can control apsl type or ease type full-automatic pressure verification platform according to database settings, and automatically complete pressurization, decompression, pressure stabilization, data recording, error analysis, printing reports and certificates.

support multiple verification platforms and multiple verification methods:

one computer can be connected with three apsl or easy full-automatic pressure calibration tables at the same time for real-time calibration. Support single test point verification, double test point verification, four test point verification, upload and download verification methods.

comprehensively manage the parameters of field instruments:

(1) management process measurement point parameters

(2) manage field instrument parameters

automatic management of verification results:

it can manage the calibration results for many years: two test results before and after adjustment.

overall management personnel and standard equipment:

(1) manage the verification personnel

(2) management personnel

(3) management standard equipment

it is convenient to generate work task list

(1) the system can print out the list of instruments that must be calibrated, the list of instruments that fail to be calibrated and the list of instruments that fail to be checked (have been scheduled for calibration, but have not been calibrated for some reason) within a certain period of time (such as a month, a week) in a very short time, which is very helpful for managers to arrange work.

(2) the pass rate before calibration can be counted.

automatically print the verification report:

the format of the verification report can be specified by the user. There can be many formats.

features of software:

integration of management and verification. The management system can directly communicate with the automatic pressure test bench or calibrator, and the verification data can be directly entered into the management database.

the verification of pressure transmitter, pressure switch and pressure indicator is integrated. The verification results are automatically identified and stored in the corresponding database.

the verification results can be entered through communication or manually. The system automatically completes error analysis and automatically generates the verification result database, verification report and verification certificate.

the system can ensure the authenticity of the verification report. The verification results are changed without legal person, which avoids the usual phenomenon of filling in the verification report by memory afterwards, so as to ensure the authenticity, credibility, science and standardization of the verification report.

this system can greatly improve the efficiency of verification.

connectable verification equipment

tmms-2000 instrument automatic verification maintenance management system can be connected with the following verification equipment:

apsl 501 series or 601 series automatic pressure calibration table or easy type automatic pressure calibration table

apsl 311 series precision pressure calibrator or 312 series precision pressure gauge

beta950 or beta960 multifunctional calibrator

beta325 pressure calibrator

beta135, 235 multi-function calibrator

Drucker calibrator

tc2000 low temperature verification furnace

classification of software:

this software is divided into network version, single machine full version, single machine 560 point software and single machine 56 point software.

(1) the network version software package supports network functions and can be used on the MIS network in the factory. It must be equipped with a server, and has the functions of on-site full-automatic pressure verification system and verification room full-automatic pressure verification system. The database capacity is 65000 points.

(2) stand alone full version software package can only be used on one computer. At the same time, it has the functions of field full-automatic pressure verification system and verification room full-automatic pressure verification system. The database capacity is 5000 points.

(3) single machine 560 point software package can only be used on one computer. At the same time, it has the functions of on-site full-automatic pressure verification system and verification room full-automatic pressure verification system, and can be connected with apsl, easy, ease calibration platforms and beta325 pressure calibrators. The database capacity is 560 points.

Related Products

平台信息提交-隐私协议

● 隐私权政策

我们致力于保护您在使用本网站时所提供的隐私、私人资料以及个人的资料(统称“个人资料”)。使我们在收集、使用、储存和传送个人资料方面符合(与个人资料隐私有关的法律法规)及消费者保护方面的最高标准。为确保您对本网站在处理个人资料上有充分信心,您切要详细阅读及理解隐私政策的条文。 本网站(下称“我们”)尊重并保护用户隐私, 特别时您一旦使用本网站,将被视为接受、同意、承诺和确认本隐私协议;您在自愿下连同所需的同意向我们披露个人资料;您会遵守本隐私政策的任何修改;您同意我们的相关业务人员就您可能会感兴趣的产品和服务与您联络(除非您已经表示不想收到该等讯息)。被收集的个人资料的种类经您的同意、我们会收集、管理和监控个人资料。

1、 适用范围

为用户提供更好、更优、更个性化的服务是本网站坚持不懈的追求,也希望通过我们提供的服务可以更方便您的需求。本隐私权政策适用于本网站提供的所有关于信息收集的服务,您访问本网站及使用本网站提供的服务均使用本隐私权政策。

2、 我们收集哪些信息

为了向您提供我们的各项服务,您需要提供个人资料信息,其中包括个人资料和不具名的资料,包括但不限于:个人资料(您的姓名、性别、年龄、出生日期、电话号码、传真号码、住址或通讯地址、电子邮箱地址等)。

3、 我们如何使用收集到的信息

收集个人资料和不具名的资料目的及用途如下:通过本网站向您提供我们的各项服务;当您使用我们的网站时,能辨认以及确认您的身份;让您使用本网站时得到为您而设的服务;本网站的相关业务人员有需要时可以与您联系;让您在使用本网站时更加方便;您提供给我们的个人资料及不具名资料,只保留到搜集的目的已达到的时候,除非因适用的法律法规之规定而继续保留。个人资料的拥有权及披露在我们网站上所收集的一切资料都由我们所拥有,不会出租或出售给任何无关的第三方。

4、 我们如何保护信息

对于个人资料的保护,我们实施妥适的实物、电子、管理的措施来保护和保障您的个人资料的安全。我们尽力确保通过本网站所收集的任何个人资料皆免于任何与我们无关的第三者的滋扰。我们采取的安全措施不限于: 实物措施:存有您个人资料的记录会被存放在有锁的地方 电子措施:存有您个人资料的电脑数据会被存放在受严格登录限制的电脑系统和存储媒体上 管理措施:只有经过我们授权的职员才能接触到您的个人资料,这些职员需要遵守我们个人资料保密的内部规则 若您知悉本网站上有任何安全方面的漏洞,请不要迟疑去联络我们,使我们可以尽快采取妥适的行动;尽管实施了上述安全措施,我们不能保证资料在互联网上的输送绝对安全,因此我们不能绝对保证您通过本网站提供给我们的个人资料及不具名的资料在一切时候都是安全的。对任何因未经授权而接触您个人资料所发生的事件我们一概不承担责任,于这方面产生或导致的任何损失和损害,我们也不负责赔偿。

5、 未成年人保护法

未成年人在无任何家长或监护人相信有未成年人在未经家长或监护人批准或同意下向本网站提供了个人自来哦,请及时联系本网站所公示电话及客服电话等,以确保资料被除去。

6、 隐私政策的修定与生效

随着本网站的服务范围扩大,我们可能适时修订《法律声明及隐私权政策》,该等修订构成本《法律声明及隐私权政策》的一部分。为避免您不能及时获知改等修订,请您经常阅读本《法律声明及隐私权政策》。无论何种方式,如您继续使用我们的服务,即表示统一受经修订本《法律声明及隐私权政策》的约束。

浏览器自带分享功能也很好用哦~

浏览器自带分享功能也很好用哦~